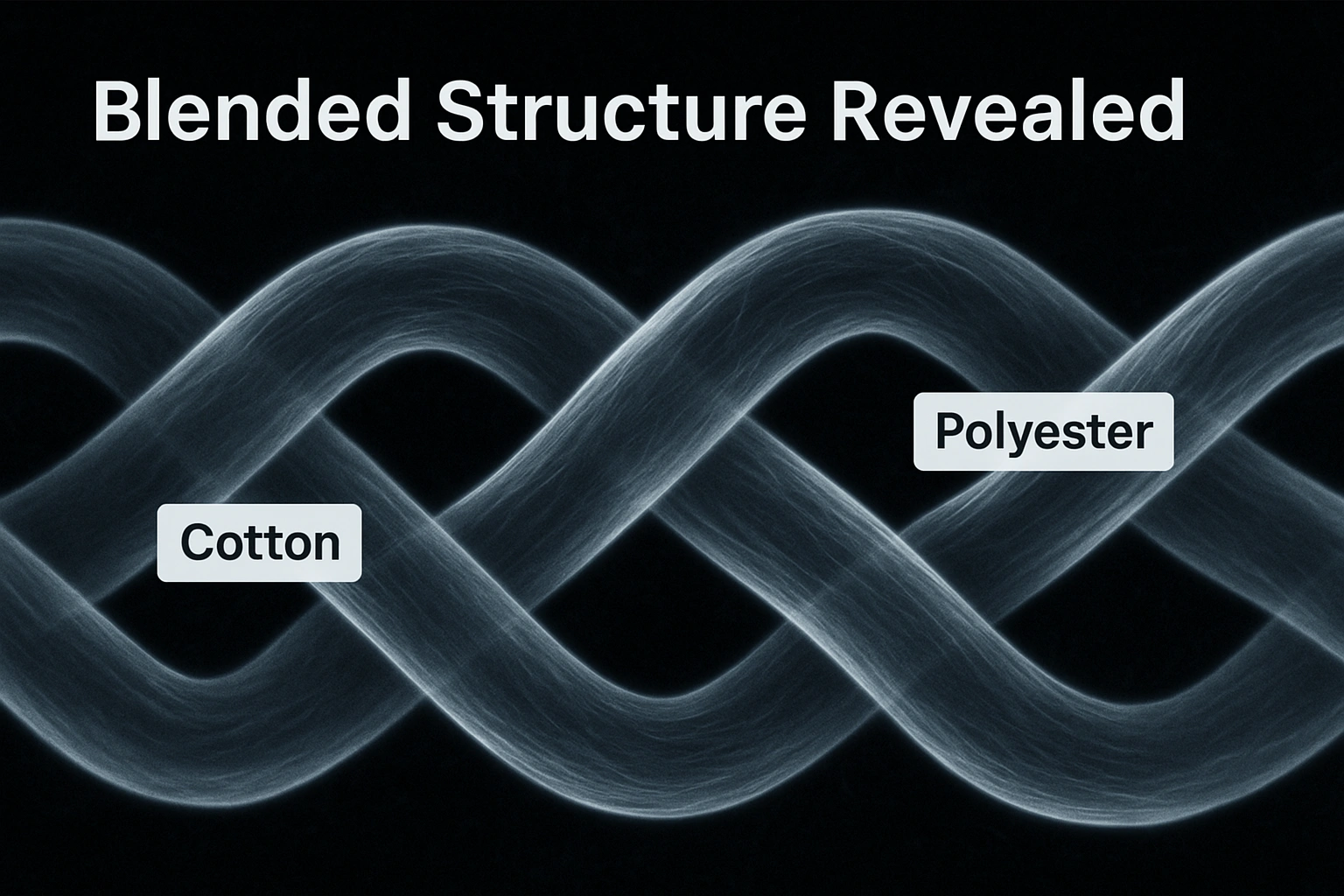

In the world of textiles, few debates are as persistent as cotton versus polyester. Cotton is widely promoted as natural, soft, and breathable, while polyester is often criticized as synthetic, less comfortable, or environmentally unfriendly. However, this common perception overlooks an important truth: polyester, especially when blended with cotton, plays a crucial role in modern fabric innovation.

This article explores eight key advantages of polyester in cotton-polyester blends:

- 1. Polyester significantly increases fabric durability and resistance to wear.

- 2. Polyester improves moisture-wicking and drying time.

- 3. It offers stronger color fastness and resistance to fading.

- 4. It supports wrinkle resistance and maintains garment shape.

- 5. Polyester helps stabilize production costs in the textile supply chain.

- 6. Recycled polyester is becoming a more sustainable fiber choice.

- 7. Many professionals prefer polyester blends, even when not marketed as such.

- 8. Fabric engineers use cotton-polyester blends to balance performance and comfort.Let’s break down each of these essential points.

1. Polyester vs Cotton: The Durability Advantage of Blended Fabrics

Cotton, while soft and breathable, is prone to tearing, shrinking, and wearing out faster than synthetic fibers. This is especially noticeable after repeated washing. Polyester, by contrast, has a higher tensile strength and is more resistant to abrasion, which means that it can significantly increase the overall durability of a garment when used in a blend.

When cotton and polyester are combined, the result is a fabric that not only feels comfortable but also withstands the test of time. This is why cotton-polyester blends are widely used in everyday clothing, from T-shirts to work uniforms. These fabrics keep their form and structure much longer than 100% cotton alternatives.

2. Moisture-Wicking Secrets: Why Cotton-Polyester Blends Stay Dry

Moisture management is one of the most important factors in fabric performance. Cotton is a hydrophilic fiber—it absorbs moisture easily and holds it. This results in garments that feel damp, heavy, and slow to dry, especially in humid or high-activity conditions.

Polyester, on the other hand, is hydrophobic. It repels water and dries quickly. When blended with cotton, polyester transforms the fabric’s moisture-handling capabilities. The result is a fabric that pulls sweat away from the skin and promotes faster evaporation.

3. Color Fastness in Fabrics: How Polyester Helps Colors Last

One of the weaknesses of cotton fabric is its tendency to fade over time. Exposure to sunlight, washing, and friction all contribute to color loss. Cotton fibers, being more porous, struggle to retain dyes over a long period.

Polyester excels in color fastness. Its smooth surface and synthetic structure bond well with dyes, especially those applied using disperse dye or sublimation printing. This means that polyester-containing fabrics retain their brightness, clarity, and color contrast through repeated use and washing.

4. Wrinkle Resistance and Shape Retention in Cotton-Polyester Blends

Anyone who has owned 100% cotton clothing knows that it wrinkles easily and can lose its original shape after a few washes. Cotton fibers, while breathable, lack elasticity and tend to deform with wear.

Polyester adds structural integrity to blended fabrics. It helps garments maintain their original shape, resist creasing, and require less ironing.

5. Fabric Costs Explained: Why Polyester Is the Economical Choice

From a production perspective, polyester offers significant cost advantages. Unlike cotton, which is affected by agricultural variables like rainfall, pests, and labor shortages, polyester is produced through a stable, industrial process. This allows textile manufacturers to scale production efficiently and predict costs more accurately.

6. Is Polyester Sustainable? Rethinking the Eco Impact of Synthetic Fibers

Polyester’s reputation as an environmentally harmful material is increasingly outdated. Although conventional polyester is made from petroleum-based sources, the rise of recycled polyester (rPET) has significantly reduced its environmental impact. Recycled polyester is made from post-consumer plastics such as water bottles, helping to divert waste from landfills.

7. Why Fashion Professionals Prefer Cotton-Polyester Fabric Blends

Although marketing language often promotes “100% cotton” as the premium option, professionals in fashion and textile production understand the technical limitations of pure cotton. For many applications, cotton-polyester blends are the behind-the-scenes favorite.

8. Fabric Engineering 101: How Cotton and Polyester Work Better Together

Modern fabric development is about engineering—not just raw materials. Blending cotton with polyester allows textile experts to fine-tune properties like softness, breathability, strength, color, and elasticity. Different blend ratios serve different purposes.

Conclusion: Polyester’s Role in the Future of Fabric

Polyester’s strengths are not a secret among textile professionals—they are part of the formula for better-performing garments. From moisture-wicking to durability, from color retention to cost efficiency, polyester delivers measurable advantages that pure cotton simply cannot match on its own.

As the industry moves toward smarter, more sustainable fabric solutions, polyester will continue to play a central role. Especially when blended with cotton, it offers a balanced approach to both comfort and performance.

Some fabric manufacturers, like ZEVA DENIM in China, already apply this strategy in practice—offering a wide range of cotton-polyester denim fabrics with fast delivery and flexible order quantities. It’s a clear sign that blended fabrics are not just a technical choice, but a market-driven one.

For consumers and brands alike, understanding the truth about cotton-polyester blends leads to better decisions and more resilient products.