Introduction

In a competitive marketplace where apparel brands constantly balance cost and quality, the allure of low-priced denim is strong. However, seasoned manufacturers know that cheap denim often hides a series of production and operational risks. From inconsistent yarns to unstable dye lots, these hidden flaws compromise not only the garment but the brand’s reputation. When price is the only metric guiding denim sourcing, businesses often pay more later through rework, delays, and dissatisfied customers.

In the global denim market, fabric pricing is often a primary factor in sourcing decisions. However, price alone does not reflect total value. Manufacturers know better than anyone that every low-cost quote is due to a reduction in specifications. Costs are cut here and there, and these reductions may affect production efficiency, quality control, product performance and brand reputation.

This article outlines the hidden costs of purchasing cheap denim from a manufacturing perspective. It aims to help buyers think deeply and re-evaluate whether low cost is really low cost, so as to make wise decisions.

So we will start from the following perspectives

- Raw Materials: Where Cost Cutting Begins

- Yarn Quality and Twisting Integrity

- Dyeing Process: Cheap Doesn’t Fade Well

- Weaving Shortcuts and Machine Downtime

- Finishing Processes: Where “Looks” Are Deceptive

- Cost of Rework, Claims, and Brand Reputation

- Smart Sourcing: Paying More, Getting More

1. Raw Materials: Where Cost Cutting Begins

Using inferior cotton, such as reclaimed fibers or low-staple blends, can lead to uneven spinning and a high number of yarn neps. This impacts dye uniformity and fabric hand feel. Mills may also skip cotton combing to reduce costs, which reduces yarn evenness. Buyers must ask about fiber source and combing method. Sustainable choices like organic cotton are often more consistent, despite a slightly higher price.

Raw material selection defines the performance of any fabric. Premium denim begins with high-staple, combed cotton that offers tensile strength, fiber uniformity, and consistent dye uptake. Low-cost alternatives often use short-staple or carded cotton, or even reclaimed fibers that vary in length and cleanliness.

Technical impact: short-staple fibers cause more lint in spinning, leading to frequent yarn breakage and uneven slubs. This requires slower machine speeds and increases downtime. Poor cotton also results in reduced fabric strength and more neps (fiber knots), which are defects during weaving and visual inspection.

Buyer’s takeaway: when evaluating denim quotes, ask about the fiber grade and type. Quality cotton minimizes rework and supports better sewing performance downstream.

2. Yarn Quality and Twisting Integrity

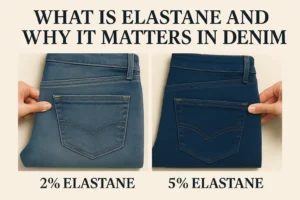

In denim, twist strength affects not only fabric resilience but also seam strength and garment lifespan. Inconsistent twisting in low-cost yarns can lead to higher needle breakage and distortion during sewing. Stretch denims made with improperly twisted yarns may suffer from poor recovery and bagging. Brands should insist on twist-level documentation during development.

The twist in yarn determines its durability, elasticity, and structural integrity. Premium denim typically uses ring-spun yarns with consistent twist levels, while cheap denim may use open-end or rotor-spun yarns with minimal twist.

Manufacturing risk: Low-twist yarns reduce yarn cohesion, leading to fraying and snapping under tension. This affects weaving tension, causes weft shift during dyeing, and results in unstable fabric widths.

From a buyer’s view: cheap yarn compromises garment construction. Stitching on low-integrity yarn causes seam slippage and poor recovery, especially in high-stress areas like knees and seat.

3. Dyeing Process: Cheap Doesn’t Fade Well

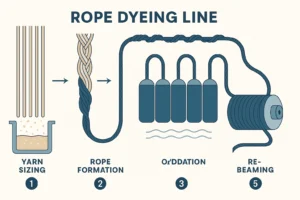

Budget denim may be dyed using quick-fix reactive or sulfur alternatives rather than pure indigo, which leads to poor crocking resistance. Color shading differences become visible post-wash, creating mismatch across garment panels. Factories that manage cost over quality may also reduce oxidation time during rope dyeing, leading to poor dye fixation and patchy fading.

Dyeing is a critical step that defines both the appearance and performance of denim. High-end denim undergoes multiple dips in indigo vats with controlled oxidation between dips. In budget production, dyeing shortcuts are common—fewer dips, faster lines, and weaker fixation.

Technical risks: weak indigo bonding leads to low crock resistance, patchy color loss, and inconsistent fading. Shade variation across rolls results in color mismatches during garment panel alignment.

Quality control issues arise when bulk shade matching fails, leading to rejected lots or costly adjustments in laundry. Buyers must ensure their suppliers use standard dyeing protocols and provide lab dips with reproducibility data.

4. Weaving Shortcuts and Machine Downtime

Poor warp tension control in low-end mills can create edge marks, inconsistent weft density, and excessive fabric skew. These issues aren’t always visible at greige stage but manifest post-finishing. Brands working with structured fits may encounter layout problems due to these subtle distortions.

Weaving defines the body and character of denim. To reduce cost, some mills increase loom speeds, reduce quality checks, or operate older looms without tension monitoring.

Technical consequence: high-speed weaving without proper beam tension creates barré, mispicks, and weft skew. These visual and dimensional defects affect fabric lay plans, cause high roll rejections, and reduce cutting room efficiency.

Manufacturers see the result in greater fabric wastage, longer inspection times, and unbalanced inventory. Buyers should request weaving specs, including loom type and average efficiency rates.

5. Finishing Processes: Where “Looks” Are Deceptive

Skipping singeing causes surface fuzz that pills after several washes. Absence of sanforization leads to 5–8% unexpected shrinkage—rendering garment fits inconsistent. These faults show up after retail, leading to high return rates. Premium finishes not only improve feel but reduce post-purchase complaints.

After weaving and dyeing, denim must be finished properly to meet shrinkage and appearance standards. Cost-cutting often involves omitting:

– Sanforization (for dimensional stability)

– Singeing (for surface smoothness)

– Tentering (for width control)

– Softening (for touch and flexibility)

Skipping these steps results in denim that shrinks unpredictably, pills after wear, or has a scratchy, synthetic hand feel.

Technical impact: garments shrink after sewing, sizes shift after laundering, and consumers feel dissatisfaction after the first wash. Buyers should always ask for shrinkage test reports and hand feel ratings before approving fabric.

6. Cost of Rework, Claims, and Brand Reputation

A poor fabric can trigger a chain reaction. Delays from re-sourcing or additional QC slow down time-to-market. Smaller brands that rely on lean inventories suffer the most. The cost of rushing replacements, covering claims, or issuing credit notes can surpass the original savings from cheap denim.

One of the most overlooked costs in apparel production is rework. In our experience, factories sourcing cheap denim are more likely to face:

– Roll mismatch during marker planning

– Seam failures after stitching

– Inconsistent shrinkage across batches

From a QA standpoint, this leads to longer inspection times, higher scrap rates, and production delays. For brands, these defects often translate into customer returns, bad reviews, and retailer penalties.

While cheap denim may reduce the initial invoice, it increases the cost of production per garment and adds risk at every stage from factory to retail.

7. Smart Sourcing: Paying More, Getting More

Forward-thinking sourcing includes not just base fabric price but trimming yield, expected cutting loss, and percentage of first-quality rolls. Experienced brands focus on consistent shrinkage rates, dye stability, and evenness of hand feel. All these enable reliable production schedules and happier retail partners.

A modest increase in fabric cost—often just $0.20 to $0.30 per meter—can yield enormous benefits in stability, performance, and predictability.

For manufacturers, better quality fabric means:

– Smoother spreading and cutting

– Fewer sewing issues like needle deflection

– Consistent outcomes in dye, shrink, and drape

For buyers, it means:

– Better fit retention in garments

– Lower return rates

– Higher perceived value by consumers

Smart sourcing isn’t about paying more—it’s about reducing total manufacturing risk.

8. ZEVA DENIM: A Reliable Denim Fabric Partner

ZEVA DENIM works closely with clients to assess seasonal performance, trend alignment, and budget balancing. We understand that each client’s success is tied to how well the fabric delivers—technically and commercially. Our Cloud Soft Yarn series, for example, combines comfort and structure, helping brands optimize fit while maintaining cost efficiency.

At ZEVA DENIM, we understand the entire lifecycle of fabric—from yarn twist to in-store sale. We supply over 200 denim fabrics developed for brands that demand consistency and flexibility.

We offer:

– Ring-spun yarns with engineered twist for stability

– Controlled dyeing with multi-dip oxidation

– Sanforized and softened finishes for ready-to-sew rolls

– Cloud Soft Yarn options for superior recovery and comfort

All available with:

– Small MOQ

– 7-day delivery

– Technical documentation

Explore our full collection at ZEVA DENIM CATALOG

Conclusion: Know the Real Cost of Cheap Denim

In the end, smart buyers look beyond cost per meter. They calculate value through conversion efficiency, rework probability, fit precision, and customer loyalty. Sourcing decisions rooted in transparency and technical knowledge lead to better garments—and more profitable outcomes.

Cheap denim may seem like a good deal—but manufacturers know it often leads to higher costs in the form of delays, defects, and damage to brand equity.

By investing in better fibers, controlled processes, and reliable suppliers, apparel brands can build garments that perform better, last longer, and deliver more value.

At every step of denim production, smart sourcing protects your product—and your reputation.