Introducción

In recent decades, the denim industry has witnessed a striking shift in fabric weight standards, with lightweight denim becoming increasingly dominant. While this change is often attributed to the fast fashion industry’s demand for speed and cost-efficiency, the real reasons go much deeper. This article dissects the multilayered factors behind the denim weight debate, from production economics and manufacturing risks to global fashion cycles and market segmentation.

This article explores:

- The evolving meaning of denim weight and its historical roots

- How industrial pressures—not just trends—reshaped denim standards

- The cost dynamics and risk profiles of producing light vs. heavy denim

- Why fashion direction shifts and what that means for fabric weight

- The realistic market space that still exists for heavyweight denim

- Sourcing strategies for brands that want flexibility and quality

1. Denim Weight: From Functional Origins to Market Signal

Denim weight traditionally signified function. Workers wore 13–16 oz fabrics because the dense weave offered durability, abrasion resistance, and warmth. Over time, as denim evolved from workwear into everyday fashion, weight became a signal of quality or authenticity—particularly in raw or selvedge segments. Today, weight plays less of a technical role and more of a stylistic and marketing one.

2. More Than Trends: What Really Drives Weight Reduction

While fast fashion often gets the blame, the reality is more structural. Shorter lead times, cost-reduction pressure, and global supply chain shifts have pushed fabric mills to optimize for yield, dye uniformity, and faster processing. Lightweight denim uses less yarn per meter, weaves faster, and is easier to handle in cutting and sewing—making it the pragmatic choice for many mass producers, regardless of style.

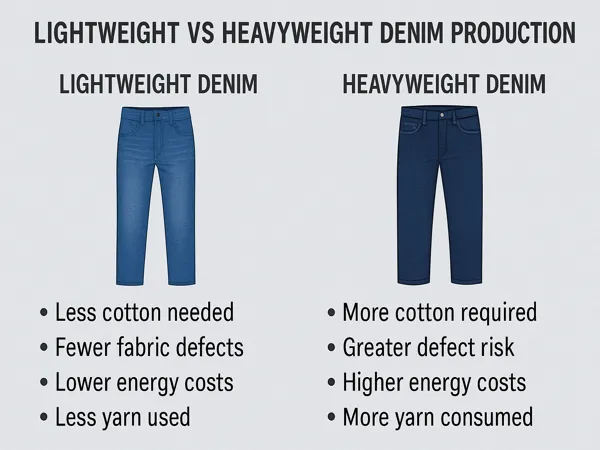

3. Economics and Risk: The Production Reality of Light vs. Heavy Denim

Producing lightweight denim lowers raw material usage and energy input, reducing direct costs. But it also changes the risk profile. Lightweight fabrics are more prone to slub visibility, seam puckering, and skewing if finishing is not controlled well. Heavier denim, while more costly to produce, often has a more stable construction and tolerates finishing variation better. However, weaving heavier fabric increases tension on looms, which raises maintenance costs and slows down throughput.

4. Fashion Direction Is a Mirror of Macro Trends

Denim silhouettes and fabric choices don’t evolve in a vacuum. When economic uncertainty rises, consumers lean toward softer, lightweight, comfortable styles—mirroring social preference for ease and speed. Global fashion direction often responds to lifestyle shifts, not just aesthetics. For example, as remote work and streetwear dominate, lightweight, stretchy denim gains relevance. But when authenticity and nostalgia rise, heavyweight denim returns to the spotlight in niche or premium markets.

5. Does Heavyweight Denim Still Have a Market?

Absolutely—but it’s a segmented one. Rather than mass-market dominance, heavyweight denim now thrives in specific niches: heritage brands, raw denim enthusiasts, custom tailors, and premium fashion lines that value storytelling and longevity. While the volume is smaller, price points and customer loyalty can be higher. The key is clear market positioning and product education—especially around fade potential, durability, and cost-per-wear advantages.

6. Brand Sourcing Strategy: Balancing Lightness, Speed, and Depth

For brands navigating this complexity, the solution lies in supplier collaboration. Mills that offer in-house R&D, sampling support, and varied weight programs enable better decision-making. For example, ZEVA DENIM—a denim fabric manufacturer in China—offers over 200 denim products, including lightweight and midweight options suitable for fast delivery and trend responsiveness. Their flexible MOQ, competitive pricing, and integrated production model help brands respond quickly to market shifts without compromising fabric variety or reliability. (More at: https://www.zevadenim.com/)

Conclusión

Blaming fast fashion alone oversimplifies a much broader shift in the denim industry. Fabric weight is the result of intersecting forces: manufacturing efficiency, consumer comfort, macroeconomic shifts, and supply chain realities. While lightweight denim meets modern needs in many ways, heavyweight denim retains its place where authenticity, performance, or storytelling matter. The future lies not in one standard weight—but in smart, flexible sourcing and product design that aligns with clear brand goals.