Introducción

When selecting denim for your next collection, you may be focused on color, wash, stretch, or sustainability—but how often do you consider the fabric’s weight as a factor in your profit margin?

Denim weight is more than just a design spec. It affects raw material usage, sewing difficulty, shipping costs, and even retail pricing. For manufacturers and brand owners, understanding the correlation between denim weight and profitability is not just helpful—it’s essential.

This article unpacks how the number of ounces per yard affects your bottom line, offering a practical guide to choosing the right weight for both design intent and financial gain.

The main points are as follows:

- What Is Denim Weight, and Why Does It Matter?

- Raw Material and Yarn Cost Implications

- Dyeing and Finishing Costs

- Impact on Manufacturing and Sewing

- Shipping, Logistics, and Duties

- Retail Pricing Strategy and Consumer Perception

- Profit Margin Math: When Heavier Isn’t Always Better

- Sourcing Smart: Finding the Right Weight for Your Brand

- ZEVA DENIM: Supporting Brands With Tailored Weight Options

1. What Is Denim Weight, and Why Does It Matter?

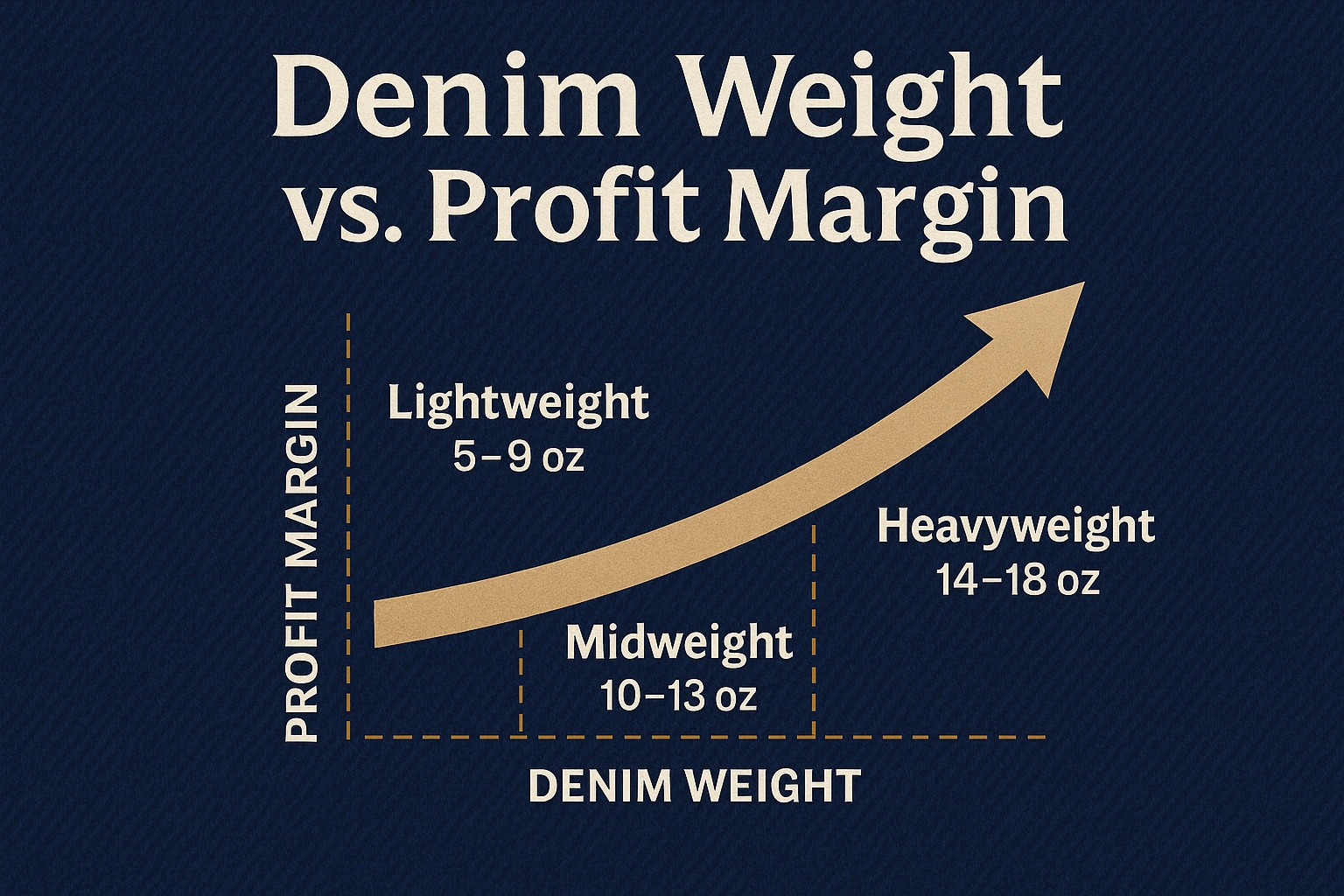

Denim weight is measured in ounces per square yard (oz/yd²), or sometimes in grams per square meter (gsm). This number reflects how much the fabric weighs before washing or finishing.

– Lightweight Denim: 5–9 oz

– Midweight Denim: 10–13 oz

– Heavyweight Denim: 14–18 oz

Weight doesn’t just influence comfort or appearance. It also affects fabric price, production workflow, and transportation costs—which ultimately shape your margin per unit.

2. Raw Material and Yarn Cost Implications

Heavier denim uses more fiber. For every ounce added per yard, mills must spin and weave more yarn—and yarn cost is a primary component of denim pricing.

A quick comparison:

– 8 oz denim = approx. 270 gsm

– 14 oz denim = approx. 475 gsm

This means a 14 oz fabric contains nearly 75% more material mass than an 8 oz one. And that cost multiplies when dyed, woven, and finished.

3. Dyeing and Finishing Costs

The more massive the fabric, the more dye it consumes.

– Heavier denim absorbs more indigo in each dip

– Requires longer fixation and rinsing

– Water and chemical usage increases

– Drying takes longer and uses more power

Finishing processes must be adjusted for heavier weights, increasing pressure and heat application, which raises costs.

4. Impact on Manufacturing and Sewing

Sewing heavier denim requires:

– Stronger needles

– More thread

– Slower line speeds

Heavy fabric dulls equipment faster and leads to slower throughput. As a result, the cost per garment increases even if the denim is marginally cheaper.

5. Shipping, Logistics, and Duties

Weight affects freight.

– Heavier denim increases carton and pallet weight

– Airfreight charges can surge on heavier orders

– Customs duties in many countries are weight-based

Overseas buyers should always calculate full landed costs—not just FOB pricing.

6. Retail Pricing Strategy and Consumer Perception

Heavier denim is perceived as more durable, but not all customers want it.

– Some prefer lightweight jeans for flexibility and breathability

– Others expect heavier denim for quality and value

Brand strategy must align fabric weight with consumer expectations. A heavy jean that costs more to make must justify a higher price tag—or you lose margin.

7. Profit Margin Math: When Heavier Isn’t Always Better

Lightweight denim allows for higher volume, faster production, and lower logistics costs. Heavy denim, while premium, comes with constraints.

– CMT costs rise

– Fewer garments per roll or container

– Risk of unsold inventory if customers don’t respond to rigid fits

8. Sourcing Smart: Finding the Right Weight for Your Brand

Don’t default to ‘heavier is better’.

– Consider seasonal relevance

– Match weight to style (e.g., structured vs. draped looks)

– Think about yield per roll and total garment output

Stretch denim innovations allow midweight fabrics to perform like both ends of the spectrum.

9. ZEVA DENIM: Supporting Brands With Tailored Weight Options

ZEVA DENIM offers over 200 denim fabrics across the weight spectrum, from light 6 oz blends to heavyweight 16 oz twills. We help brands match the right fabric weight with their pricing, style, and customer profile.

We provide:

– Small MOQ

– Fast sampling and production

– Customizable GSMs and yarn constructions

Our Cloud Soft Yarn is available in multiple weights, ensuring comfort with performance.

Conclusion: Weight Isn’t Just a Feature—It’s a Financial Strategy

Denim weight influences every part of your business—from fabric cost and sewing efficiency to freight and final retail performance. It is a design choice and a margin decision.

To optimize profitability, brands must understand how weight factors into both aesthetics and supply chain economics.

At ZEVA DENIM, we’re here to help you find that perfect balance.