In the denim manufacturing process, sizing and dyeing are two essential stages that define the durability, comfort, and appearance of the final product. While these procedures are often taken for granted, they play a crucial role in determining how denim fabric performs during weaving, finishing, and ultimately in the hands of consumers.

This article explores the key methods used in denim sizing and dyeing, how they impact the fabric’s properties, and what considerations designers, manufacturers, and buyers should keep in mind when selecting materials. It is divided into the following points.

- Introduction to Denim Sizing and Dyeing

- Denim Sizing: Purpose and Methods

- Indigo Dyeing: The Core of Denim Identity

- Sulfur Dyeing: For Colors Beyond Blue

- Environmental Considerations in Dyeing (Excluding Foam Dyeing)

- Combined Sizing and Dyeing Lines

- Choosing the Right Method for Your Denim Line

- ZEVA DENIM: Your Partner in Sizing and Dyeing Excellence

1. Introduction to Denim Sizing and Dyeing

Sizing is the application of a protective adhesive coating to the yarns before weaving. It strengthens the yarn, improves abrasion resistance, and reduces breakage during the weaving process.

Dyeing is the process of coloring the yarn, typically the warp yarn in denim, to achieve the classic blue shade or other fashion-forward colors.

Together, these processes ensure that the yarn can withstand the stress of weaving and that the final denim has the right color, performance, and aesthetic qualities.

2. Denim Sizing: Purpose and Methods

Purpose of Sizing

– Improve yarn strength

– Enhance abrasion resistance

– Reduce hairiness and dust during weaving

– Improve fabric uniformity

Common Sizing Agents

– Starch (natural and modified)

– Polyvinyl alcohol (PVA)

– Carboxymethyl cellulose (CMC)

– Acrylic-based polymers

Sizing Methods

Single End Sizing:

– Used for smaller batches or specialty denim

– Individual warp yarns are coated before weaving

– Offers high control, but lower efficiency

Slasher Sizing:

– Most common method for mass production

– Warp yarns are grouped and passed through a sizing solution and then dried

– Often combined with slasher dyeing, making it economical and efficient

Considerations:

– The choice of sizing agent affects recyclability and effluent treatment

– Excessive sizing may lead to stiffness and poor dye penetration

3. Indigo Dyeing: The Core of Denim Identity

Indigo dyeing is the hallmark of traditional denim. It provides the deep blue shades and the signature fading behavior denim is known for.

Types of Indigo Dyeing Methods

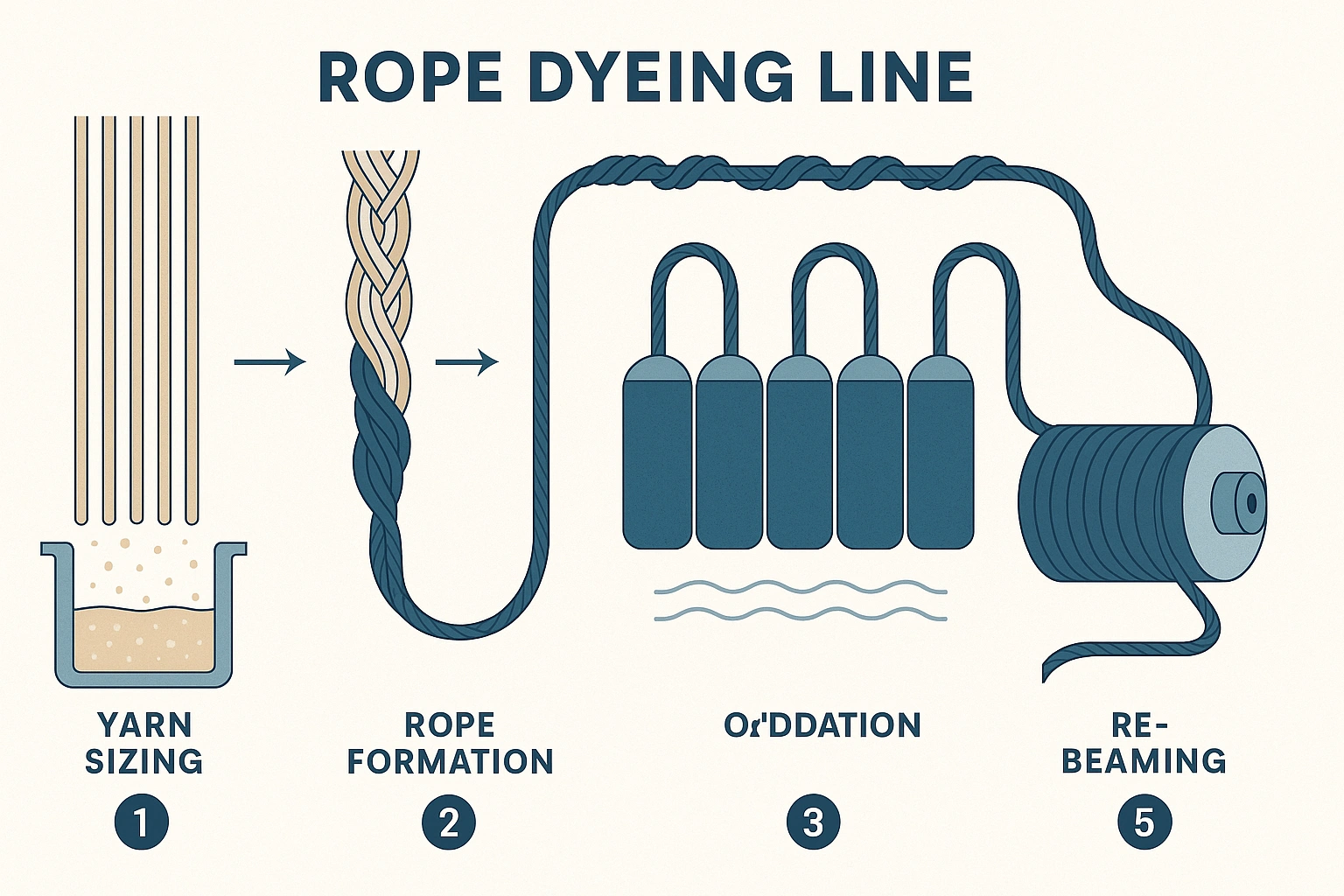

Rope Dyeing:

– Considered the premium method

– Warp yarns are twisted into ropes and dipped multiple times into indigo dye baths

– Yarns remain white in the core, leading to beautiful fading and vintage effects

Advantages:

– Deep, rich color with high fade potential

– Better oxidation and less streaking

Disadvantages:

– Requires more space and investment

– Not ideal for small runs

Slasher Dyeing:

– Warp yarns are laid flat and passed through dye baths and dryers

– More cost-effective and suitable for large-scale production

Advantages:

– Faster production

– More consistent color across batches

Disadvantages:

– Less ring-dye effect compared to rope dyeing

Indigo Characteristics

– Requires oxidation to fix color

– Prone to crocking and bleeding in early washes

– Can be overdyed or finished to control appearance

4. Sulfur Dyeing: For Colors Beyond Blue

Sulfur dyes are used to produce a wide range of denim shades, including black, grey, brown, olive, and mustard.

Application Methods

– Can be applied before or after indigo (for overdye effects)

– Typically used for warp or weft yarns, depending on the desired color contrast

Advantages

– Strong color saturation

– Good colorfastness to washing

– Affordable compared to reactive or vat dyes

Considerations

– May lead to fabric brittleness if not properly neutralized

– Some sulfur colors can oxidize over time, turning reddish or dull

5. Environmental Considerations in Dyeing (Excluding Foam Dyeing)

Denim dyeing, particularly with indigo and sulfur dyes, has historically been water- and chemical-intensive. Although there are innovative technologies like foam dyeing in the market, this article focuses strictly on traditional denim dyeing practices.

Challenges:

– High water consumption in rope dyeing

– Use of reducing agents like sodium hydrosulfite in indigo dyeing

– Generation of wastewater containing salts, sulfates, and other chemicals

Improvements:

– Pre-reduced indigo to reduce chemical load

– Advanced filtration and Zero Liquid Discharge (ZLD) systems

– Eco-friendly auxiliaries in sizing and finishing

6. Combined Sizing and Dyeing Lines

Modern denim mills often integrate sizing and dyeing into a single production line, especially with slasher dyeing and slasher sizing.

Benefits:

– Reduced processing time

– Lower energy consumption

– Better consistency between dyed and sized yarns

Limitations:

– Less flexible for design variation compared to rope dyeing

7. Choosing the Right Method for Your Denim Line

| Goal | Recommended Sizing & Dyeing Method |

| Premium fading effect | Rope dyeing + slasher sizing |

| Budget-friendly colored denim | Slasher dyeing + integrated sizing |

| Non-blue denim | Sulfur dyeing + slasher sizing |

| Sustainable goals | Pre-reduced indigo + eco-friendly sizing agents |

8. ZEVA DENIM: Your Partner in Sizing and Dyeing Excellence

When sourcing denim fabrics with reliable sizing and dyeing methods, partnering with a capable manufacturer is critical. That’s where ZEVA DENIM excels.

About ZEVA DENIM

ZEVA DENIM is a leading denim fabric manufacturer in China, integrating R&D, production, and marketing. The company offers:

– Over 200 classic and innovative denim fabrics

– Expertise in rope dyeing, slasher dyeing, and slasher sizing

– Competitive pricing and low MOQ

– Fast delivery, typically within 7 days

Whether you’re building a premium selvedge collection or bulk-ordering black denim for fast fashion, ZEVA DENIM provides consistency, performance, and support for your needs.

🌐Visit زيفا دينم to request fabric swatches or discuss your sourcing goals.

خاتمة

Sizing and dyeing may seem like backstage operations in denim production, but they are truly the unsung heroes of fabric quality and design.

Proper sizing ensures yarn strength and weaving efficiency. Appropriate dyeing methods give denim its iconic look, whether you’re aiming for vintage blue fades or bold solid colors.

From traditional rope dyeing for authenticity to sulfur dyeing for versatility, and from starch-based sizing to advanced polymers, every choice influences your denim’s story.

By understanding these processes and choosing the right partners like ZEVA DENIM, brands can create garments that are not only beautiful but also efficient to produce and satisfying to wear.